SCP/ACP Series High-Efficiency Centrifugal Pumps

Professional Industrial Pumping Solutions – High Performance, Durable, Reliable, and Easy Maintenance

Product Overview

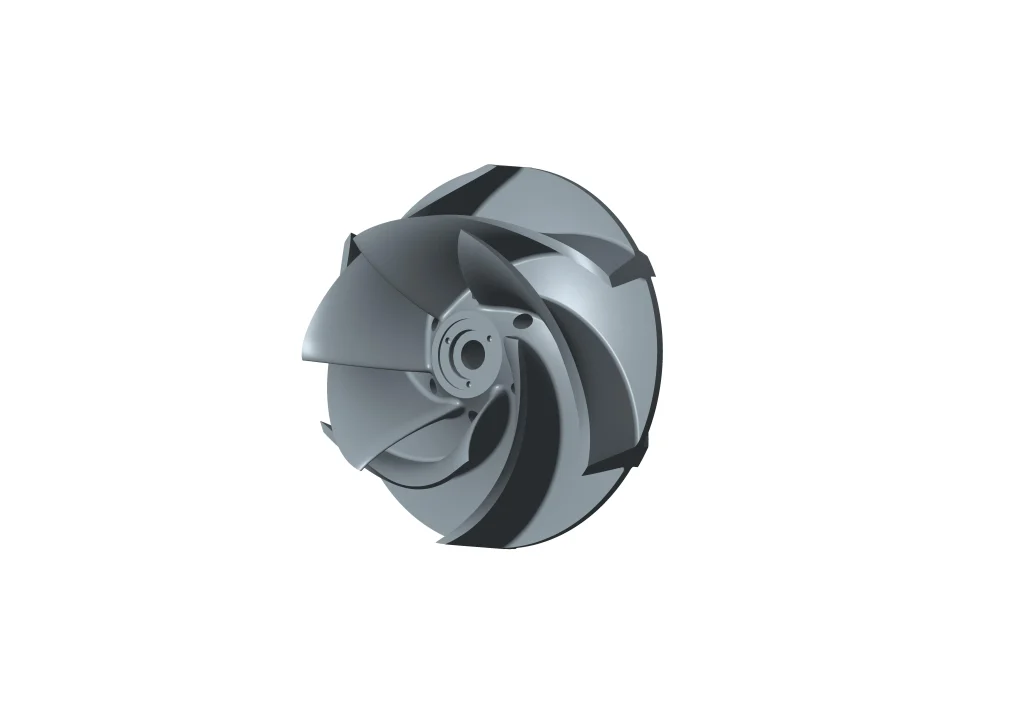

The SCP/ACP series single-stage centrifugal pumps incorporate advanced engineering design concepts, combining high performance, reliability, and flexibility. Their innovative wear-resistant open impeller design, low axial force, and wide flow channels make them suitable for conveying various media, from clean liquids to contaminated media containing solid particles.

SCP/ACP series pumps meet the highest requirements of industrial customers in terms of efficiency, service life, maintenance convenience, and economic efficiency, making them ideal for various demanding applications. Our pumps undergo rigorous testing to ensure excellent performance under various operating conditions.

Core Features and Advantages

High Efficiency and Energy Saving

Advanced hydraulic design and precision manufacturing processes achieve efficiency up to 90%, significantly reducing energy consumption and operating costs.

Excellent Reliability

Robust construction and high-quality materials ensure long-term stable operation in harsh conditions, reducing downtime.

Easy Maintenance

Modular design reduces spare parts inventory, mechanical seals and other wearing parts are durable and easy to replace, lowering maintenance costs.

Intelligent Monitoring

Optional Industrial Internet of Things (IIoT) integration enables real-time monitoring of equipment operating status and predictive maintenance.

Wide Application Adaptability

Modular design allows configuration according to specific application requirements, adapting to various process conditions and media characteristics.

Low Noise Operation

Optimized hydraulic design and precision balancing technology ensure low vibration and low noise operation, improving the working environment.

Impeller Type Selection

The SCP/ACP series pumps offer various impeller designs to meet different application requirements and media characteristics. Each impeller type has its unique advantages and application scenarios:

Our technical team can recommend the most suitable impeller type based on your specific media characteristics and process requirements to ensure optimal pump performance and lifespan.

Technical Specifications

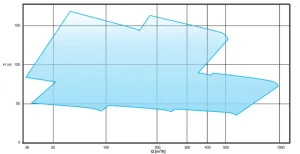

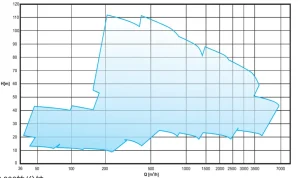

The SCP/ACP series centrifugal pumps offer various models and configurations to meet different industrial application needs. The following are typical technical parameters for standard models:

| Parameter | Value/Description |

|---|---|

| Pump Type | Single-stage Centrifugal Pump |

| Flow Range | Up to 9,000 m³/h |

| Pressure / Head | Pressure up to 40 bar / Head up to 190 m |

| Operating Temperature | -20°C to +200°C (depending on model and seal options) |

| Solid Handling Capacity | Can handle media containing solid particles, concentration up to 8% |

| Efficiency | Up to 90% |

| Drive Type | Electric (standard), other drive options available |

| Connection Size (DN) | 50 – 400 mm (can be customized according to requirements) |

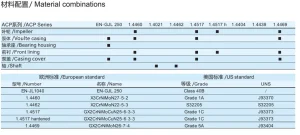

Material Selection

The SCP/ACP series pumps offer various material options to adapt to different media characteristics and operating conditions, ensuring optimal performance and lifespan:

In addition to standard material options, we also provide special alloys and custom material solutions to meet special application requirements. Our engineering team can provide material selection guidance to ensure long-term reliable operation of the pump.

Application Fields

With their excellent performance, reliability, and material selection flexibility, SCP/ACP series centrifugal pumps are widely used in the following industrial fields:

- Water and Wastewater Treatment: Water supply systems, drainage pumping stations, various process flows in wastewater treatment plants

- Chemical and Petrochemical: Various chemical media transportation, process pumping, circulation systems

- Oil and Gas: Upstream extraction, midstream transportation, downstream refining processes

- Power Industry: Power plant cooling water circulation, ash slurry transportation, desulfurization systems

- Mining and Mineral Processing: Slurry transportation, tailings treatment, process water pumping

- Paper and Pulp: Pulp transportation, wastewater treatment, chemical additive dosing

- Food and Beverage: Optional sanitary design, suitable for slurries, juices, dairy products, etc.

- Pharmaceutical and Biotechnology: Process pumping that meets sanitary standards

- Marine and Shipbuilding: Seawater lifting, ballast water, fire fighting systems

- Construction and Municipal: Building water supply, drainage systems, fire water supply

- Irrigation and Agriculture: Large-scale agricultural irrigation, drainage systems

- Seawater Desalination: Reverse osmosis pretreatment and high-pressure pumping

Optional Configurations and Intelligent Systems

The SCP/ACP series pumps offer various optional configurations and intelligent systems to meet specific application requirements:

- Multiple Seal Options: Including mechanical seals, packing seals, etc., adapting to different media and operating conditions

- Intelligent Monitoring System: Can be equipped with vibration, temperature, pressure sensors for condition monitoring and predictive maintenance

- Variable Frequency Drive: Optional frequency conversion control for precise flow and pressure regulation and energy-saving operation

- Explosion-Proof Design: Optional explosion-proof certification for hazardous areas

- Heating/Cooling Jackets: For handling high viscosity or easily solidifying media

- Multiple Installation Methods: Horizontal, vertical and other installation options to adapt to different space limitations

- Custom Coatings and Linings: Special lining and coating options to enhance wear or corrosion resistance

| Type | Type | Type | Type | Type | Type |

|---|---|---|---|---|---|

| ACP 32-125 | ACP 32-160 | ACP 32-200 | ACP 40-125 | ACP 40-160 | ACP 40-200 |

| ACP 40-250 | ACP 50-125 | ACP 50-160 | ACP 50-200 | ACP 50-250 | ACP 50-315 |

| ACP 65-125 | ACP 65-160 | ACP 65-200 | ACP 65-250 | ACP 65-315 | ACP 65-330 |

| ACP 80-160 | ACP 80-200 | ACP 80-250 | ACP 80-315 | ACP 80-400 | ACP 100-200 |

| ACP 100-250 | ACP 100-265 | ACP 100-315 | ACP 100-330 | ACP 100-400 | ACP 100-480 |

| ACP 100-500 | ACP 125-250 | ACP 125-265 | ACP 125-315 | ACP 125-400 | ACP 125-625 |

| ACP 150-250 | ACP 150-315 | ACP 150-400 | ACP 150-480 | ACP 150-500 | ACP 200-400 |

| ACP 200-480 | ACP 200-500 | ACP 200-625 | ACP 250-315 | ACP 250-480 | ACP 250-625 |

| ACP 300-400 | ACP 300-700 | ACP 350-480 | ACP 350-650 | ACP 400-330 | ACP 400-700 |

| ACP 450-550 | ACP 500-650 | ACP 600-555 | ACP 700-640 |

Get Professional Consultation and Quotation

Our pump technology experts are happy to provide you with detailed technical information, selection advice, and customized solutions. Please contact us for more information or to arrange an on-site demonstration.