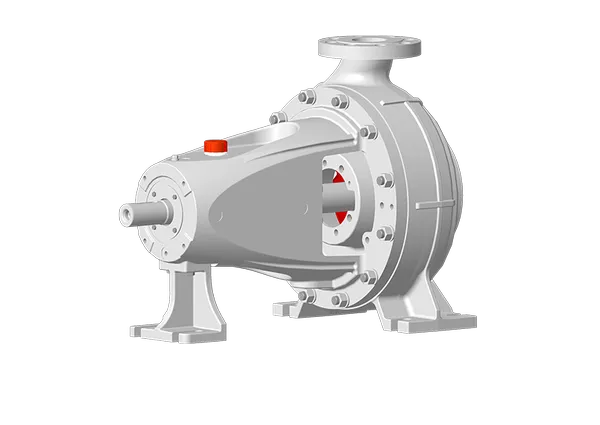

WP/HW Series High-Efficiency Wear-Resistant Centrifugal Pump

Specially designed for handling media containing solid particles, fibers and other highly abrasive materials

Product Overview

The WP/HW Series high-efficiency wear-resistant centrifugal pump is an industrial pump specially designed for handling media containing solid particles, fibers and other highly abrasive materials. Using advanced wear-resistant technology and optimized hydraulic models, this pump series demonstrates excellent wear resistance and operational reliability in harsh working conditions such as papermaking and wastewater treatment.

Key components of the WP Series pump adopt thickened design and special wear-resistant materials, significantly extending equipment service life while maintaining high efficiency and energy saving characteristics. The modular design concept enables this pump to be flexibly configured according to specific application requirements, making it an ideal choice for handling abrasive media.

Structural Features

- Key components such as pump casing, impeller and cover adopt thickened designWear Enhancement

- Back pull-out design allows internal inspection and maintenance without disconnecting pipelines

- Heavy-duty bearing assembly with high-quality lubrication system ensures long-term stable operation

- Special wear-resistant mechanical seals adapt to high wear working conditions, extending service life

- Optimized volute and impeller design reduces vortex and local wear

- Robust base design ensures stable pump operation and reduces vibration

- Standardized interface design facilitates integration and installation with existing systems

- Multiple shaft seal options to meet different media and working condition requirements

Impeller Types

The WP/HW Series pump provides various impeller designs to adapt to different application requirements:

| Impeller Type | Features | Suitable Media |

|---|---|---|

| Closed Impeller | High-efficiency design, stable operation | Suitable for media containing small amounts of particles |

| Semi-Open Impeller | Clog-resistant design, easy maintenance | Suitable for media containing medium solid particles or fibers |

| Non-Clog Impeller | Excellent passage capability, superior wear resistance | Specifically designed for high solid content, easily clogged media |

All impellers undergo precision balancing tests to ensure smooth operation and are manufactured with wear-resistant materials to extend service life.

Technical Parameters

| Parameter Type | Range | Unit |

|---|---|---|

| Flow Range | 10 – 7000 | m³/h |

| Head Range | 5 – 100 | m |

| Pressure Range | Up to 16 | bar |

| Temperature Range | -20 to +140 | °C |

| Inlet Diameter | 50 – 300 | mm |

| Outlet Diameter | 40 – 250 | mm |

| Rotation Speed | 1450 / 2900 | rpm |

Note: The above parameters are for standard models. Customized solutions can be provided according to customer requirements.

Material Selection

The WP/HW Series pump provides multiple wear-resistant and corrosion-resistant material options to adapt to different media corrosiveness and abrasiveness requirements:

Different flow component material combinations can be provided according to specific working condition requirements to ensure optimal performance and life balance.

Application Fields

The WP Series wear-resistant centrifugal pump is widely used in the following fields:

Paper Industry

Waste paper pulp transportation, pulp circulation, white water treatment, etc.

Wastewater Treatment

Sludge transportation, primary sedimentation tanks, aeration tank circulation, etc.

Power Industry

Ash transportation, desulfurization systems, circulating water treatment

Chemical Industry

Corrosive slurries, catalyst suspensions, etc.

Other Industries

Metallurgy, food processing and other solid-containing media transportation