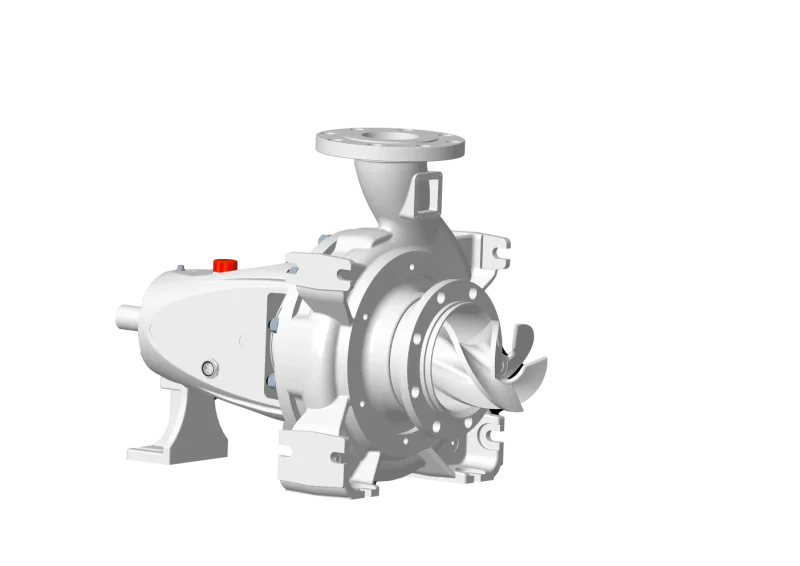

MC Series Medium Consistency Pumps

Product Series

MC Series Medium Consistency Pumps offer various models to meet different flow rate and head requirements

| Model | Model | Model |

|---|---|---|

| MC80-350 | MC100-330 | MC100-500 |

| MC125-450 | MC150-470 | MC200-550 |

| MC250-600 | MC300-660 | MC400-700 |

Structural Features

MC Series Medium Consistency Pumps feature innovative design to ensure efficient and reliable performance

Spiral-Centrifugal Composite Impeller

The core uses a single-blade three-dimensional spiral impeller. The inlet section forms a spiral positive displacement pump structure to achieve forced suction of high-concentration media; the outlet section converts to a centrifugal impeller to increase head. This design solves the clogging problems of traditional centrifugal pumps and can handle pulp concentrations up to 12% or sewage with solid content up to 14%.

Modular Sealing and Bearing System

Shaft seals support packing seals (standard type ≤80°C) and double mechanical seals (high temperature type ≤120°C), with optional dynamic seals (no external water required). Heavy-duty bearing housing with oil lubrication or grease lubrication adapts to high temperature and high pressure conditions (such as 180°C, 25bar).

Degassing and Wear Resistance Enhancement

Efficiently separates gas from the slurry, avoiding cavitation and improving operational stability. Flow components (impeller, liner) can be coated with wear-resistant coatings or hardened to extend service life.

Non-Clogging Flow Channel Design

Extra-large flow channel design allows passage of solid particles with diameters of 40–150mm (such as bagasse, slaughter waste), ensuring smooth operation and reducing clogging and maintenance requirements.

Technical Parameters

Performance parameter range of MC Series Medium Consistency Pumps

| Parameter | Range |

|---|---|

| Flow Rate | Up to 800 L/s (approx. 2,880 m³/h) |

| Head | Up to 250 m |

| Temperature Range | -80℃ ~ +180℃ |

| Pressure | Up to 25 bar |

| Particle Passage Diameter | 40–150 mm |

| Concentration Range | 6%~18% for pulp, sludge, biomass, etc. |

Material Selection

Graded material solutions for flow components according to different corrosion and wear requirements

Pump Body/Cover Materials

HT200 cast iron, SS304, duplex steel 1.4460

- Suitable for general neutral slurry → highly corrosive media

- Good corrosion resistance

- High mechanical strength

Impeller/Wear Liner Materials

2Cr13 stainless steel, duplex steel 1.4517 (hardened)

- Suitable for high-wear slurries (such as pulp, slag)

- Extremely high wear resistance

- Extends equipment service life

Shaft Materials

1.4021 stainless steel, duplex steel 1.4462

- Meets high torque and anti-bending requirements

- Excellent mechanical properties

- Suitable for heavy-duty conditions

Special Application Materials

Full stainless steel flow path (SS316L)

- Suitable for food and pharmaceutical industries

- Complies with FDA standards

- Hygienic design

Detailed Material Selection Description

Graded material solutions for flow components according to different corrosion and wear requirements

| Component | Material Options | Application Scenarios |

|---|---|---|

| Pump Body/Cover | HT200 cast iron, SS304, duplex steel 1.4460 | General neutral slurry → highly corrosive media |

| Impeller/Wear Liner | 2Cr13 stainless steel, duplex steel 1.4517 (hardened) | High-wear slurries (such as pulp, slag) |

| Shaft | 1.4021 stainless steel, duplex steel 1.4462 | High torque and anti-bending requirements |

| Special Applications | Full stainless steel flow path (SS316L) | Food and pharmaceutical industries, FDA compliant |

| Sealing Components | Silicon carbide, alumina ceramic, hard alloy | High wear, high corrosion conditions |

| Wear-Resistant Coatings | Tungsten carbide, ceramic composites | Extreme wear environments, extends component life |

Application Areas

MC Series Medium Consistency Pumps are widely used in the following industries and process scenarios

Pulp and Paper

MC Series Medium Consistency Pumps are used in the pulp and paper industry to transfer medium consistency pulp, especially suitable for cooking, bleaching sections, and headbox feed systems.

Specific Application Scenarios:

- Pulp transfer systems with concentration ≤7%

- Waste paper pulp recycling processes

- Chemical mixing and transfer in bleaching sections

- Paper machine headbox feed systems

Municipal Environmental Protection

In the environmental protection field, MC pumps are used to treat sludge with solid content up to 14%, suitable for sewage treatment plants and sewage pumping stations.

Specific Application Scenarios:

- Sludge thickening and dewatering in sewage treatment plants

- Solid-liquid mixture treatment in municipal sewage pumping stations

- Industrial wastewater treatment systems

- Sedimentation tank sludge recovery and treatment

Beet Pulp Sugar Industry

MC pumps are used in the sugar industry for beet pulp transfer, molasses treatment, and high-viscosity media transfer in sugar production processes.

Specific Application Scenarios:

- Beet pulp transfer and concentration

- Molasses recovery and treatment systems

- Media transfer in sugar production processes

- Waste residue treatment and resource utilization

Energy and Chemical

In the energy and chemical fields, MC pumps are suitable for biomass fuel slurry, geothermal injection brine, and highly corrosive slurry transfer in chemical plants.

Specific Application Scenarios:

- Biomass fuel preparation and transfer

- Geothermal energy injection systems

- Highly corrosive media treatment in chemical plants

- Catalyst slurry preparation and transfer

Food and Pharmaceutical

MC pumps are used in the food and pharmaceutical industries for hygienic transfer, suitable for high-viscosity media such as molasses, starch slurry, as well as dairy products, pharmaceutical liquids, etc.

Specific Application Scenarios:

- Food-grade high-viscosity media transfer

- Pharmaceutical liquid preparation systems

- Dairy product processing

- Hygienic fluid handling systems

Contact Us

Get more detailed information and professional consultation on MC Series Medium Consistency Pumps

China (Shanghai) Pilot Free Trade Zone

+86 136 1188 4189

hmtec99@163.com