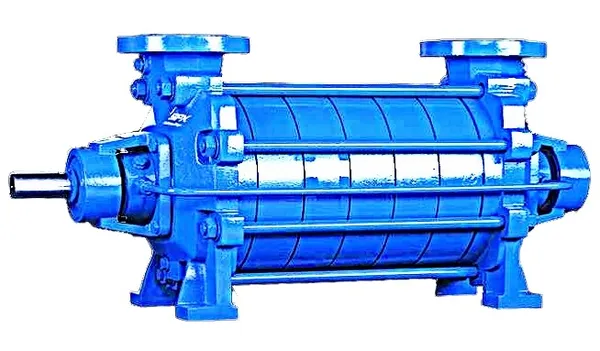

MD Series Horizontal Multistage Centrifugal Pump

Product Overview

The MD Series Horizontal Multistage Centrifugal Pump is a high-performance industrial pump specifically designed for high-pressure fluid transfer requirements. Manufactured using advanced engineering technology and premium materials, this pump ensures stable and reliable operation even under demanding conditions. Widely used in various industrial fields, it is an ideal choice for applications such as boiler feed water, high-pressure cleaning, and process transfer.

Structural Features

- Horizontal multistage design, compact structure, small footprint

- Automatic axial force balancing, stable operation, low vibration

- Precision-machined flow components, high efficiency, low energy consumption

- Modular design, easy maintenance, quick spare parts replacement

- Heavy-duty bearing housing ensures long service life

- Reliable shaft sealing system, various sealing options available for different working conditions

Impeller Type

The MD Series pump features closed impellers designed with efficient hydraulic models. The optimized blade profile ensures smooth flow and pressure output. Multiple impellers are arranged in series, with each stage effectively increasing the medium pressure to achieve the required total head.

Technical Parameters

| Parameter Type | Value Range |

|---|---|

| Flow Range | 20-1,300 m³/h |

| Head Range | 300-1200 m |

| Working Pressure | Up to 12 MPa |

| Medium Temperature | Maximum 180°C |

| Inlet Diameter | DN50-DN200 |

| Design Standards | ISO 5199 / API 610 |

Material Selection

| Component | Standard Material | Optional Materials |

|---|---|---|

| Pump Body, Impeller | CA6NM Martensitic Stainless Steel | 2205 Duplex Steel, 2507 Super Duplex Steel, 304 Stainless Steel, 316 Stainless Steel |

| Shaft | High-Strength Stainless Steel | Customizable based on medium characteristics |

| Sealing Ring | Non-metallic Material | Reinforced Non-metallic Composite Material |

Material selection can be optimized according to specific medium characteristics, temperature, and pressure requirements to ensure optimal corrosion resistance and service life. Sealing rings use non-metallic materials with excellent sealing performance and wear resistance.

Application Fields

Main Applications:

- Boiler Feed Water Systems – Thermal power plants, industrial boiler rooms

- High-Pressure Cleaning Equipment – Industrial equipment cleaning, pipeline cleaning

- Industrial Process Pumping – Chemical, petroleum, natural gas industries

Suitable Media:

- Clean water, pure water, deionized water

- High-temperature hot water (maximum 180°C)

- Slightly corrosive chemical liquids

- Various industrial fluids without solid particles

Industry Applications:

- Power Industry: Power plant boiler feed water, condensate recovery

- Petrochemical Industry: Process transfer, high-pressure injection

- Steel Metallurgy: Cooling systems, descaling systems

- Municipal Engineering: High-rise building water supply, fire protection systems

- General Industry: High-pressure testing, circulation systems

Product Advantages

High Efficiency & Energy Saving

Optimized hydraulic design ensures high-efficiency operation, significantly reducing energy consumption costs

Reliable & Durable

Premium materials and precision manufacturing processes guarantee long-term stable operation

Easy Maintenance

Modular design facilitates daily maintenance and component replacement

Wide Applicability

Multiple material selections and configuration options meet various working condition requirements